The scope of services of M&P

- Concept development for future cooling at BHW Hameln

- Planning with 3D CAD model, support in awarding tenders and property monitoring

- Immediate measures in the cooling water network due to acute germ growth

- Renovation of the open evaporative coolers and separation of the hygienically relevant spray water circuits from the cooling water system through retrofitting of heat exchangers

In 2016, BHW Hameln commissioned the M&P team to develop the future concept for cooling. The focus was on possible technologies and increasing plant redundancy, keeping economic considerations in mind.

The key points of the renovation concept:

- Increase in the number of cooling generators with the same power distribution to expand plant redundancy

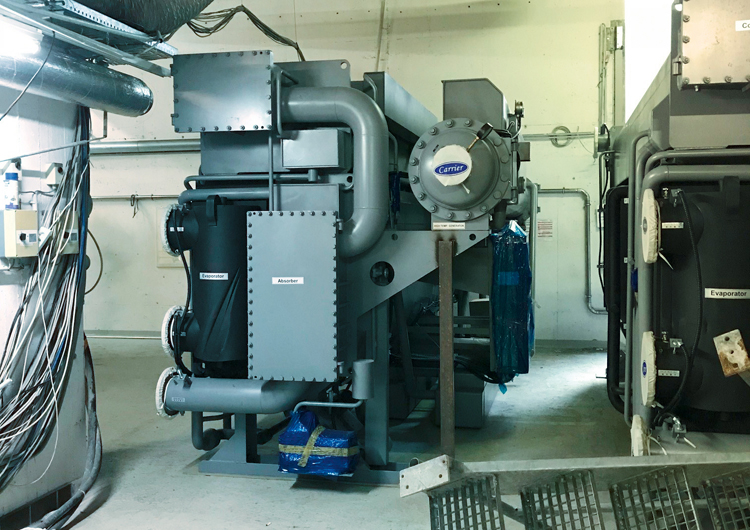

- More flexibility in energy use through a combination of electrical and thermal cooling

- Exploitation of technological progress with a reduction in energy costs of approx. €50,000 p.a. net

- Temporary retention of recooling until a later second construction phase

Since refurbishment of the plant technology and automation for cooling generation is only possible in the winter half-year and the delivery time for cooling generators of the required size is half a year, the conversion was set for the winter of 2017/2018.

In June 2017, M&P was commissioned with the further planning, support in awarding tenders and the property monitoring. Due to the time frame of only one year for the planning and implementation, the tendering of the cooling generators was brought forward. At the same time, we put together the necessary planning (3D CAD model) and put in place additional tenders.

German germ-removal efficiency

Then came a huge problem: as part of microbial investigations in line with the 42nd German Federal Immission Control Act (BImSchV (08-2017)), an inadmissible level of contamination was detected in the circulating water of the existing recooling system. Immediate measures in the cooling water network only brought about a temporary improvement in water quality. The project team was faced with a difficult task. Due to the long delivery times, it was no longer possible to implement a new recooling system in the winter of 2017/2018. New recoolers with system separation would have required massive structural extensions. On the other hand, the use of dry coolers would have had a significant negative impact on the efficiency of the cooling supply.

With the help of M&P, a solution was quickly found: renovation of the open evaporative coolers and separation of the hygienically relevant spray water circuits from the cooling water system through retrofitting of heat exchangers. A measuring field for water monitoring and biocide vaccination was provided for each of the open water cycles.

Making the impossible possible

Once quick approval came from the client, there was no time to lose. The action plan: project planning of the recooling, integration of the additional measures into the ongoing project, development of a control concept and tendering of the additional services. Ready-to-execute planning was already wrapped up and sitting under the Christmas tree. The last outstanding bill of quantities was ready on cue for the fireworks to mark the beginning of 2018.

Thanks to the trusting cooperation between all parties involved (BHW, CSG, M&P, Carrier, as well as the local companies AME-Technik and INGA), the seemingly almost impossible was achieved. Once the existing systems had been dismantled, the new cooling generators were installed, the complete media supply and process automation were set up, and it was possible to gradually put the new cooling supply with a nominal output of 8,000 kW into operation on time, starting on 25 April 2018.