The scope of services of M&P

- Active support of a company-wide energy efficiency initiative, the Saving Initiative Energy

- Diverse implementation of measures for energy generation, energy saving and substitution

- Creation of a technical road map for the company’s individual CO2 savings target

- Additional sustainability boosters through review of funding opportunities by M&P funding experts

ZF Friedrichshafen AG is one of the world’s largest automotive suppliers. The company’s success story began over 100 years ago with the construction of gears and gearboxes. Today, the service portfolio covers a broad field of expertise in sustainable mobility technology. M&P adds another future-oriented cog to the gears – in a company-wide energy efficiency initiative.

ZF is a globally active technology Group and supplies systems for the mobility of passenger cars and commercial vehicles, as well as industrial technology. With a comprehensive product range, ZF offers holistic solutions for established automotive manufacturers, as well as mobility providers and newly emerging companies in the field of transport and mobility.

One focal area of the further development of ZF’s systems is digital networking and automation on the path to becoming a software- and cloud-based company. The ZF Group is represented at 188 production sites in 31 countries and 18 main development sites in 8 countries.

ZF was founded in 1915 and has developed from its beginnings as a specialist supplier to the aviation industry into a global mobility technology corporation.

With its future-oriented products, ZF is aiming for ‘next-generation mobility’ for passenger cars, commercial vehicles and industrial applications.

Proactive identification of energy-saving potential

ZF is a highly innovative and versatile technology company for which many gears need to mesh together perfectly, not only in its products, but also throughout the entire company and chain of locations. That makes us all the more pleased that M&P has been a suitable cog in the gears at ZF since 2020. In addition to providing consulting in the reorganisation of FM processes, we have been supporting a company-wide energy efficiency initiative for two years: the Saving Initiative Energy was launched by ZF’s energy managers to identify and implement energy-saving potential.

The initiative is not an end in and of itself. Rather, it supports ZF’s sustainability efforts in a special way. The company has set itself the goal of being climate-neutral by 2040 at the latest – ten years earlier than required by the EU.

‘Sustainability is an integral part of the Group’s strategy. The overarching goal is to reconcile society’s mobility needs with the conditions of a healthy ecosystem. We must ensure that all our activities respect the limits and, at the same time, lead to sustainable and future-proof solutions. That is why ZF has developed a climate strategy: the company should be climate-neutral by 2040. This means that by then, no ZF locations will cause CO2 emissions, neither through self-generation nor through the purchase of electricity.’ Wolf-Henning Scheider, CEO of ZF

The measures in energy efficiency consulting and in the sustainability approaches employed at the production sites to achieve the ambitious targets are interlinked.

Viewed from a high altitude, the mostly identical sprockets form an interlocking sequence.

Efficiency

Energy saving is the first important point. Energy that is not needed in the first place causes no energy consumption, no CO2 emissions and no costs. The savings potential in our projects is between 5 and 30% depending on the location, sector and success of previous optimisation efforts.

Substitution

Often underestimated or not recognised: due to different responsibilities, departments and competencies, ‘gears’ often do not mesh together optimally. This results in substitution potential. Industrial contexts include highly energy-intensive processing or production steps. Either energy (as waste heat) is released by a thermal combustion process or higher-value electrical energy is converted into heat by friction during mechanical processing.

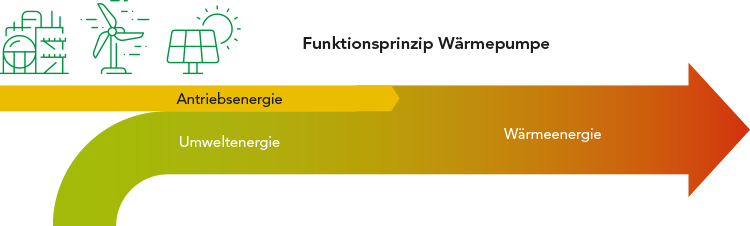

With a system analysis and, where appropriate, the use of physically advantageous effects, for example through a heat pump, these losses can be used to substitute the energy required for heating or cooling real estate. Sometimes it is even possible to use waste heat to generate electricity using an ORC process.

Production/procurement

After optimising efficiency and using lost energy flows, one question remains: how do you deal with energy procurement? Depending on individual and regional conditions, there are possibilities for self-generation of energy in suitable situations. This can involve familiar technologies such as photovoltaic or wind power plants, but also more ambitious, future-oriented technologies such as PVT modules, pyrolysis or fuel cells.

For the remaining energy that needs to be purchased, we recommend renewable energies, which politicians and society – at least in Germany – intend to make available more extensively in the coming years.

Against the background of long-term CO2 reduction targets, the technical requirements of tomorrow should be considered in all new and replacement technical investments today. We help our customers by providing them with a technical road map with an individual CO2 reduction target for the next five to ten years.

Financial sustainability boosters

At ZF, M&P experts have so far been able to provide valuable information on increasing energy efficiency, substitution and self-generation at more than 15 locations in Germany and other European countries. The initiative is planned to continue to a similar extent in 2022.

In addition to the valuable contributions to the corporate goal and the reduction of energy costs, such initiatives can also save maintenance and investment costs. This money can be used for sustainability measures as an additional financing effect.

There is another sustainability booster in the shape of the multiple funding opportunities that the German federal government has made available for industry. If, for example, plant technology to be refurbished is not exchanged like for like, but is combined with innovative concepts for waste heat recovery from production, or old methods are abandoned in order to transform fossil fuels into renewable energy sources, then funding for up to 50% of the investment costs can be provided with the help of M&P’s sustainability and funding experts.

Saving, substitution, generation, funding: at each stage, we are guided by the idea of allowing the gears to mesh perfectly for the plant managers, engineers, energy and environmental managers and many employees at ZF.

The energy efficiency measures from ZF and M&P mesh together perfectly at SI Energy.

Key facts:

- M&P had examined 24 plants (production sites) in 6 countries and 18 cities by the end of 2021.

- More than 450 ideas, potential measures and concrete measures were defined and evaluated in terms of investment costs and possible savings. Some of the measures have already been implemented.

- If all the ideas are implemented, more than 175 GWh can be saved. That corresponds to approximately 55,000 t CO2 – about the amount that 55,000 beech trees would sequester over the course of their 80-year life.

- In order to sequester this amount in the year of emission, rather than over 80 years, an area of 80,000–100,000 ha would have to be planted, i.e. 800–1,000 km² (in comparison: Berlin has an area of 891 km²).

Images: © ZF Friedrichshafen AG